A country known for its forward-thinking environmental practices, Sweden leads the world in developing high-impact sustainable designs. In the spirit of eco-friendly innovation, the Swedish start-up Wayout International recently committed their efforts to scaling back plastic waste and pollution caused by the beverage industry. The result is a revolutionary way of brewing and producing popular drinks, with minimal environmental impact: beverage micro-factories.

The concept of micro-factories is simple. Instead of shipping bottles across the globe and polluting the air through fossil-fuel transportation, micro-factories allow communities, restaurants, and breweries to produce beverages and purified water in-house, reducing the need for transportation and logistics. The goal of this concept is to localize drink production everywhere, so that even communities with limited resources can produce safe drinking water, without contaminating surroundings with plastic or glass bottles.

How It Works

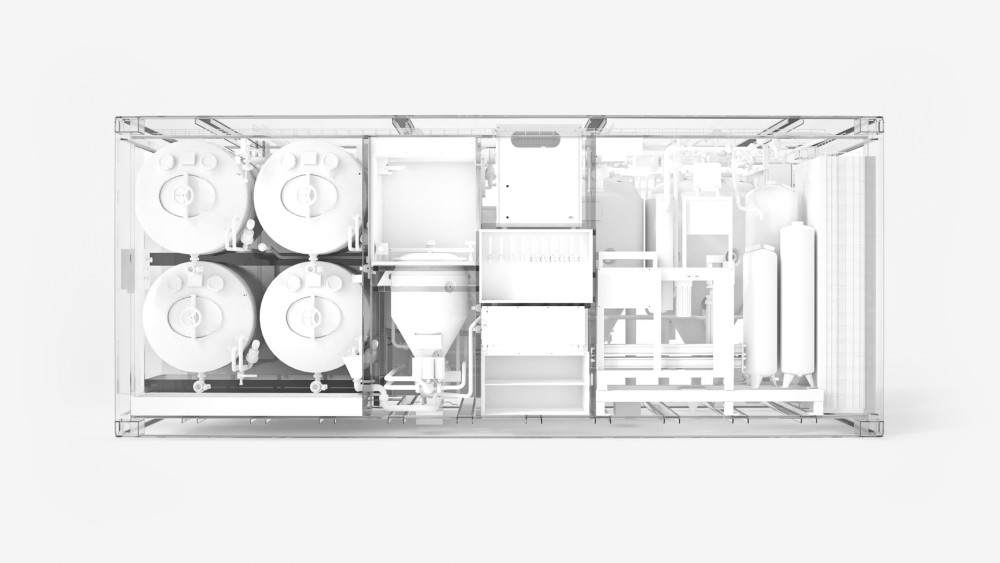

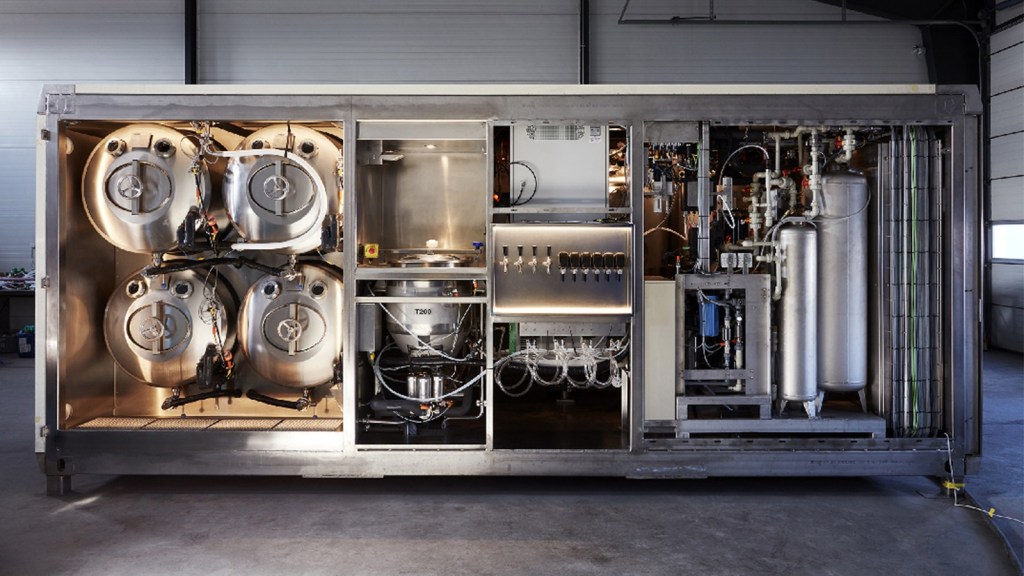

The micro-factory is a marvel of modern invention, capable of brewing and concocting an array of beverages that suit unique business needs. It can brew cider, beer, soda, and flavored water, but that’s not all. The product has the ability to desalinate and re-mineralize sea water, creating fresh water with or without carbonation. In fact, some of the first micro-factory models have been shipped to Nairobi and the Serengeti to service communities where potable water is a scarce resource. The possibilities for this contraption are endless; it has the potential to expand access not just to tasty beverages and brews, but also to life-sustaining water where it is needed most.

Also, impressive, the engineers at Wayout International took special care to eliminate any adverse environmental impact of their products. The micro-factory system runs on solar panels and has the ability to recycle water and energy internally. Because the machine encourages local production, the start-up estimates that each module can eliminate eight tons of Co2 pollution and a quarter million bottles from the landfill every month. Pitched as a “box of miracles,” micro-factories promise to overhaul the way the market transports, produces, and manufactures everyday beverages, making the process gentler on vulnerable eco-systems.

User Friendly, Business Savvy

Aside from its environmentally friendly attributes, the micro-factory model promises to boost profitability and efficiency as well. Monthly, the machine can hold up to 3,000 liters of brewed beverages and store up to 70,000 liters of water. Because distributors only need to purchase extracts and ingredients for the amount they use, they can tailor costs according to their enterprise’s individual needs. Eliminating excessive waste, the micro-factory offers an exciting combination of accessibility, sustainability, and cost-effectiveness, launching the next wave of innovative manufacturing.

Additionally, the micro-factory is easy to use; it features a plug-and-play design, controlled by a smartphone app. While ingredients and extracts are loaded manually, everything else is automated, from the brewing process to the cleaning functions. The app even provides instructions for mixing beverages and allows users to monitor the progression of the brewing process virtually. The company handles all of the shipping and assembly and distributors can order products through the app, so there is no need to fret about transitioning to this novel method of beverage production.

Micro-factories testify that reducing the beverage industry’s harmful environmental impact is not only possible but also pragmatic. When companies like Wayout value and prioritize sustainability, new, disruptive ideas emerge, ideas that can affect positive change—one beverage at a time.