Rogue Industries is a Maine based maker operation. The company was started in 2007 when the founder, Michael Lyons, developed excruciating lower back pain and created a curved front pocket wallet prototype – that was 650,000 wallets ago.

After Rogue Industries introduced their patented curved front pocket wallet in 2007, it became a dream of the company to actually make their own products. “How hard could that be?”, thought Michael Lyons, Founder.

In 2015 the company purchased an abandoned farm house along with a workshop on 14 acres in Standish, Maine. The effort involved with the details of setting up actual production presented a steep learning curve. Their very first production hire was a lady with extensive stitching and sail making experience- but none in leather. She is still with them and now runs the shop.

Rogue acquired an industrial splitter to thin the leather down, a 10 ton hydraulic press to cut the thick pieces of leather from the hides, and a dizzying array of very specialized and rather pricey sewing machines for both leather and waxed canvas. “The finished product simultaneously looks both simple and elegant- but the expertise and technology which goes into it are more involved than I would have ever believed,” says Lyons.

- Alligator

- Moose

- Horween Bison

- American Bison

- Minimalist Spartan

He continued by disclosing “A colleague of ours who had previously run a well known leather bag company in New York called me up and asked if I was crazy when we were considering setting up a stitching facility. He reminded me of the fact that I knew nothing about leather stitching.”

The colleague was right. Rogue Industries had designs, patents and ideas- but no experience in actually producing finished goods. The first few items created were early stage prototypes and couldn’t even be sold. Then the next set got better. And better again. Rogue learned about the nuances of leather stitching and finishing. They say that it has not been an easy path to set up a small maker factory here in the US- but it’s rewarding to take an idea on paper and create a beautifully finished product worthy of being on the World stage.

And it’s equally as rewarding to take a customer into their Workshop and show them where the leather comes in, how it gets selected, cut, stitched and polished.

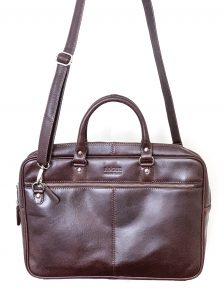

- Bison Leather Crossbody Bag

- Mt Blue Leather Duffle

The essence of Rogue’s modest success is not trying to sell their unique wallet design to everyone. It’s finding the few customers that appreciate the distinctive design, like Jon Stevens that recently called in from Newtown, Pennsylvania and unsolicited, said “This wallet is genius.”

Specializing in curved front pocket wallets, the company has expanded from one single initial offering to over 80 unique designs ranging from duffle bags, totes, belts, and brief cases to laptop bags.

- West End Briefcase

- Fore Street Leather Tote

Their materials of preference are high end specialized leathers such as American Bison, Moose, Salmon and Steer. Waxed canvas offerings have been added to the line to compliment the leather designs. Amazingly, 70% of their designs are now made in Maine.

Enjoy 15% off by using code JS15